Debugging

One of the new features I could have utilized this time, thanks to the programming SWD interface, was using the mEDBG programmer and Atmel Studio 6.2 for debugging the code as I was writing it.

To recapitulate, I've been using the mEDBG programmer/debugger IC on a SAMD10 Xplained Mini board (details on necessary modifications in the previous post). This non-standard approach works, but it requires a few changes in Atmel Studio's settings. To just program a custom board with the Xplained Mini programmer, one can follow the steps described in the previous blog post. But to use it for debugging custom boards as well, the project in Atmel Studio has to be created for ATSAMD10D14AM device, so the Xplained board appears among available tools. This, however, means that the whole toolchain gets setup for SAMD10 microcontroller instead of the desired SAML21. To bypass this, I did the following. First, I downloaded Atmel.SAML21_DFP.1.2.120.atpack package from Microchip's pack repository, and copied the SAML21B's include folder to the following path in the Studio's toolchain which added some new files and overwrote several older files:

Atmel Toolchain\ARM GCC\Native\4.8.1443\CMSIS_Atmel\Device\ATMEL\saml21\

This was to update all the Studio's scripts and dependencies since I was working with Atmel Studio 6.2 which originally supported only pre-production versions (A) of the target MCU while the TT7B tracker ran on SAML21E17B microcontroller. I then went on to modify these files:

Atmel Studio 6.2\Devices\ATSAMD10D14AM.xml

Atmel Toolchain\ARM GCC\Native\4.8.1443\Resources\SamDeviceNameToHeaderMapping.xml

Atmel Toolchain\ARM GCC\Native\4.8.1443\CMSIS_Atmel\Device\ATMEL\saml21\include\sam.h

Atmel Toolchain\ARM GCC\Native\4.8.1443\CMSIS_Atmel\Device\ATMEL\saml21\include\saml21.h

The links contain the already modified versions of the files for download. The bottom three files contain only small changes. Mostly just altering paths of the ATSAMD10D14AM device. The contents of the first, however, were almost entirely replaced with the contents of ATSAML21E17B.atdf file from the downloaded pack.

As a result of these modifications, when the selected device for a new project is ATSAMD10D14AM, the Xplained board shows up among the available debugging tools. However, all the dependencies, linkerScripts and startup/system libraries loaded in the Solution Explorer are for the desired SAML21E17B microcontroller. Using a dedicated programmer such as Atmel-ICE would naturally do without these modifications.

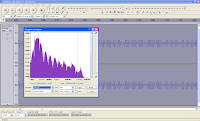

An illustration of what debugging allows the user to do can be seen in the screengrabs above. Here, I tested a simple piece of code to verify that functions I had written to enable/disable different oscillators and clock domains of the microcontroller worked properly. The debugging interface allows placing breakpoints (lines highlighted in red) throughout the code where the debugger stops the code execution while providing access to the current states of all registers. In case a newly written code hangs at some point, the debugger can also highlight the exact line where the code execution stopped.

| Clock | I [μA] | V [V] | P [μW] |

|---|---|---|---|

| OSC16M - 4MHz | 279 | 1.5 | 419 |

| OSC16M - 8MHz | 477 | 1.5 | 716 |

| OSC16M - 12MHz | 669 | 1.5 | 1004 |

| OSC16M - 16MHz | 834 | 1.5 | 1251 |

| OSC32K - 32kHz | 75 | 1.5 | 113 |

| XOSC32K - 32kHz | 74 | 1.5 | 111 |

| DFLL48M - 48MHz | 1413 | 1.5 | 2120 |

| FDPLL96M - 48MHz | 1414 | 1.5 | 2121 |

| XOSC32K - Standby | 9 | 1.5 | 14 |

I used this piece of code and its variations to check a number of possible ways to clock the microcontroller. The table above summarizes the power consumption of the whole TT7B board running on the specific clock source at a specific frequency. The board was detached from the debugger and supplied from a 1.5V LDO at its battery input port during the measurements. The current flowing from the LDO to the board was measured with μCurrent in the microampere setting.

In these instances, I used the debugger to access the current contents of chosen arrays. In the first example, I was able to verify that functions I had written to directly read (and write) the MCU's non-volatile memory (flash) worked properly. In the second case, every iteration of the FOR loop filled RX_Buff with bits and pieces of NMEA sentences transmitted by the GPS module which allowed me to confirm that the module was operating correctly and able to acquire a GPS lock.

Firmware

Github repository

With the help of the debugging interface, I eventually wrote and tested a number of libraries to control various peripherals of the MCU and to provide the functionality I had envisioned in the original design. The complete firmware for TT7B tracker in its current state can be found in the link above.

The whole code was written in Atmel Studio. All the necessary information on how to make a peripheral operate properly is contained in the microcontroller's datasheet. Chapters dedicated to individual peripherals generally describe the principles of operation, outline the steps necessary to initialize the peripheral, and describe all associated registers in detail. The resulting code itself, then, is mostly sequences of register manipulations that realize the desired peripheral behavior. For example, the WatchDog library (in the screenshot above) was among the first pieces of code I had to write, because by default the microcontroller has the WatchDog timer enabled, and without either the code resetting the timer periodically, or the code disabling it at the beginning, the MCU is reset whenever the timer runs out - every few seconds.

Following WatchDog, I continued in coding several core libraries such as two oscillator controllers (OSC), a generic clock controller (GCLK) and a power manager (PM) which all conduct basic MCU operation. In general, the microcontroller requires a source of a clock signal to step through and execute the programmed instructions. This is where the oscillator controllers come in allowing to choose from a number of options such as external crystals, internal oscillators, or a high speed digital frequency locked loop (DFLL48M) and a fractional digital phase locked loop (FDPLL96M). These source clock signals can then be individually prescaled and distributed to specific peripherals via the generic clock controller. The GCLK provides up to 9 generators (the main clock, MCLK, sourcing GCLK[0]) each being able to utilize a different source and supply different peripherals of choice. Running the device at frequencies higher than 12MHz requires switching it to a higher consumption Performance Level 2 (PL2) control of which, along with various sleep modes, is in the hands of the power manager.

A peripheral such as an analog-to-digital converter (ADC), digital-to-analog converter (DAC), real-time counter (RTC), etc. is typically made operational by first selecting a source GCLK generator and enabling a peripheral channel (PCHCTRLx register) to provide the peripheral with a clock signal. Following that, registers in the peripheral's domain can be set up and the peripheral enabled by setting the enable bit in the peripheral's CTRLA register.

A consequence of the possibility to run parts of the MCU at different frequencies manifests itself in the need to synchronize some of the peripheral's core registers with the rest of the microcontroller when written. This is in practice done by an empty while loop repeatedly checking a specific bit in the peripheral's SYNCBUSY or STATUS registers until it is cleared or set. That provides the required delay before executing further instructions.

The TT7B board is divided into several domains that can be individually powered up or down as described in the tracker's design. The manipulation of the general purpose I/O pins mediating this enable/disable functionality is carried out by the I/O pin controller (PORT). In some cases, such as the ADC and DAC, a peripheral utilizes I/O pins to input or output a signal. In these instances, the control over said pins has to be given to the peripheral. This again is in competency of the I/O pin controller (PMUXEN bit in PINCFG register).

Transmitter

The transmitter utilizes the digital-to-analog converter (DAC), two timer counters (TC) 0 and 4, and the inter-integrated circuit (I2C) interface mode of the serial communication interface (SERCOM) peripheral. The actual initialization routines and register configurations for the IC are then gathered in a separate library - SI5351B. Since the operation of the transmitter is a little bit more complex, it is outlined in this section.

First I soldered a temporary SMA connector to the transmitter output which also served as an accessible spot for attaching a probe. The oscilloscope I used when working on the transmitter was Owon VDS1022I with 100MS/s sampling rate which somewhat limited its usefulness to frequencies up to only 10 to 25MHz.

These screengrabs show what the output signal looked like when the Si5351B was programmed to lower frequencies - specifically at 1MHz, 5MHz, 10MHz and 25MHz. The 1MHz signal was most likely deformed by the 2.2nF DC blocking capacitor forming a high-pass filter with the 50Ω load impedance (cut-off frequency of around 1.5MHz). The reconstruction accuracy of the 25MHz signal then suffered from the oscilloscope's low sampling rate.

One of the open questions was how much RF power could the IC deliver as its advertised usage was as a clock generator not a transmitter. There were four configurable drive strength settings in the Si5351B's registers titled as 2, 4, 6 and 8mA (CLKx_IDRV[1:0]). The screengrabs above show the resulting signal amplitudes for the different drive strengths when configured to output a 10MHz signal to a 50Ω termination. These observed amplitudes combined with the following equation were the basis for my first attempt to estimate the output power. $$P=\Bigg(\frac{V_{p-p}/2}{\sqrt{2}}\Bigg)^2/R$$ where $P$ is the output power in watts, $V_{p-p}$ is the signal's measured peak to peak voltage, and $R$ is the load impedance in ohms - in this case 50Ω. Note that this RMS voltage calculation applies to sinusoidal wave forms while the discussed signal contains also higher frequency harmonics. The results are in the following table.

| Drive Strength | Vp-p [V] | P [mW] | P [dBm] |

|---|---|---|---|

| 2mA | 0.88 | 1.94 | 2.87 |

| 4mA | 1.64 | 6.72 | 8.27 |

| 6mA | 2.10 | 11.02 | 10.42 |

| 8mA | 2.70 | 18.22 | 12.61 |

The peak to peak voltages in the table differ from the voltages seen in the screengrabs as they varied a little in time, and I tried to use the mid values for the calculations.

To confront the previous results with another method, I reached for AD8318 which I had used when measuring output power of my TT7F trackers. Transmitting a 144MHz carrier wave through a 30dB attenuator directly to its input, the RF detector output voltages corresponding to the following power levels in dBm:

| Drive Strength | P [mW] | P [dBm] |

|---|---|---|

| 2mA | 1.48 | 1.70 |

| 4mA | 5.25 | 7.20 |

| 6mA | 9.33 | 9.70 |

| 8mA | 12.49 | 10.97 |

This time the results were lower but at least in the same ballpark. Nevertheless, I wanted to know more and did the same measurements while transmitting 1MHz, 10MHz and 100MHz carrier waves subsequently.

| Drive Strength | P1 [mW] | P1 [dBm] | P10 [mW] | P10 [dBm] | P100 [mW] | P100 [dBm] |

|---|---|---|---|---|---|---|

| 2mA | 0.40 | -3.99 | 0.45 | -3.47 | 1.32 | 1.20 |

| 4mA | 0.78 | -1.07 | 1.58 | 2.00 | 4.79 | 6.80 |

| 6mA | 0.88 | -0.55 | 2.57 | 4.10 | 9.55 | 9.80 |

| 8mA | 0.92 | -0.38 | 3.16 | 5.00 | 13.66 | 11.35 |

The 100MHz results were more or less comparable to the initial 144MHz measurement, however the 1 and 10MHz carriers recorded much lower output power. Especially the 10MHz results being 6-7dB lower compared to the results produced by the first method were a bit confusing. In case of the 1MHz signal, lower output was expected due to the probable high-pass filtering mentioned earlier. Unfortunately, I don't have a high sample rate oscilloscope at hand, so I can't really probe the 144MHz signal and see how effective the designed low-pass filtering is.

Having familiarized myself with the Si5351B's output, I moved on to modulating the carrier wave via the SAML21's digital-to-analog converter output fed to the Si5351B's VC pin. Throughout the time I was developing the code, I extensively used the oscilloscope to monitor the DAC's output by probing around the RC filter with a thin pin extended from the probe. A general description as well as a specific implementation of the AFSK modulation that will be discussed here can be found in my earlier blog post on APRS.

On TT7B, the code initializes two timer counters, each for one tone - 1200Hz and 2200Hz. By running the timers at much higher frequencies, the code can step through lookup tables which contain values from 0 to 4095 that represent a single wavelength of a sine wave which are then fed to the 12-bit digital-to-analog converter. When timed right, the output of the DAC is a continuous sine wave of the desired frequency. As timing is critical, the stepping through tables and feeding the DAC is all done in the timer counter's interrupts. The interrupt managing the 1200Hz tone also takes care of the transmission's bit rate (switching between transmitting a '0' or a '1') since that is for APRS 1200bps as well.

I mentioned lookup tables in plural. That is because due to pre-emphasis the 1200Hz and 2200Hz tones should differ in amplitude. A quite detailed discussion on pre- and de-emphasis in APRS transmissions can be found here. I decided to avoid inflating the interrupt handlers with instructions recalculating the adjustments, and instead stored two lookup tables in RAM, one for each tone.

These screengrabs show the two tones and their frequency content after FFT when two lookup table arrays of 16 elements each were used in their production. For some reason, the oscilloscope software temporarily reported the frequency as 2000Hz in the second FFT display, however the peak is shown correctly at 2200Hz. Note that the tones have different amplitudes, but are centered around a common mid point of 0.9V.

In this case, the timers ran at a faster pace and two 32 element lookup tables were used to produce the tones. The signals look cleaner and the FFT supports that observation as well. The cost is the need to clock the microcontroller at a higher frequency.

These are snippets of an actual APRS transmission. The one on the left generated by a 16 element lookup table and an MCU running at 16MHz, and the one on the right produced by a 32 element lookup table and the microcontroller clocked at 25MHz. Because of this modulation approach the transitions between tones are inherently phase continuous, however the differing amplitudes lead to noticeable jumps when the code goes from one lookup table to the other. The overall frequency content of the transmission seems slightly cleaner in case of the 32 element lookup table.

| Settings 1 | Settings 2 | Settings 3 | |

|---|---|---|---|

| REFCLK | XOSC32K | XOSC32K | XOSC32K |

| LDR | 2009 | 2009 | 1545 |

| LDRFRAC | 15 | 15 | 14 |

| FDPLL96M | 65,894,400Hz | 65,894,400Hz | 50,688,000Hz |

| GCLK[0].DIV | 4 | 2 | 2 |

| MCLK: GCLK[0] | 16,473,600Hz | 32,947,200Hz | 25,344,000Hz |

| GCLK[1].DIV | 16 | 6 | 12 |

| DAC: GCLK[1] | 4,118,400Hz | 10,982,400Hz | 4,224,000Hz |

| TC0.COUNT | 858 | 1716 | 660 |

| TC0 interrupt | 19,200Hz | 19,200Hz | 38,400Hz |

| TC4.COUNT | 468 | 936 | 360 |

| TC4 interrupt | 35,200Hz | 35,200Hz | 70,400Hz |

| Lookup 1200hz | 16 | 16 | 32 |

| Lookup 2200hz | 16 | 16 | 32 |

When working on the timing of the modulation, I tried a number of OSC/MCLK/TC setups out of which the three specific cases described in the table above were proven to work. The point was to find such a main clock frequency that would allow oversampling the 1200Hz and 2200Hz tones using only whole integer clock divisors and TC count values. The lower limit for main clock frequency was then determined by the length of the interrupt routines in terms of instructions. To produce the sine waves at desired frequencies, the microcontroller has to be able to execute the whole code within the two interrupts between individual timer counter's compare matches, and hence interrupt firings. For example, to produce the 2200Hz tone from a 16 element lookup table, the TC4's interrupt has to fire with a frequency of 16 * 2200Hz = 35,200Hz. That can be achieved by setting the timer to fire a compare match interrupt in 468 clock cycles provided the main clock runs at 35,200Hz * 468 = 16,473,600Hz. That at the same time means there are 468 clock cycles to execute whatever code is within the interrupt. To have the microcontroller operate at said frequency, the FDPLL96M can be setup to run at 65,894,400Hz using LDR and LDRFRAC values, representing the multiplier of a reference frequency, of 2009 and 15, respectively (equation in the datasheet). The reference itself is then set to be XOSC32K which on TT7B is a 32.768kHz TCXO. GCLK[0], which is the main clock, is set to source signal from the FDPLL96M and divides it by four. The operating frequency of the DAC (provided by GCLK[1]) is not that important. It just has to be fast enough to finish a conversion between individual lookup table steps.

To make this all work, I had to use two 16-bit timer counters, one for each tone. TC0, the main timer counter, is not only responsible for generating the 1200Hz tone, but also decides which bit, or rather which tone, to transmit now by enabling/disabling TC4's compare match interrupt responsible for the 2200Hz tone. In practice, proper timing of the next interrupt is achieved by adding a respective number of counts to the timer's COMPARE register (designated as TCx.COUNT in the table above).

| VCXO Pull | 0.0V | 0.913V | 1.826V | Bandwidth |

|---|---|---|---|---|

| 30ppm | -4344Hz | -1918Hz | 507Hz | 4851Hz |

| 38ppm | -5502Hz | -2430Hz | 643Hz | 6145Hz |

| 40ppm | -5792Hz | -2558Hz | 677Hz | 6469Hz |

| 50ppm | -7240Hz | -3197Hz | 846Hz | 8086Hz |

| 240ppm | -34752Hz | -15346Hz | 4060Hz | 38812Hz |

Si5351B allows setting the degree to which voltage present on its VC pin pulls the output frequency in parts-per-million. The selectable settings range from +-30ppm to +-240ppm. Since on TT7B the Si5351B operates at 3.3V (3.27V when measured on the actual board), and the microcontroller's DAC outputs voltages in range of 0V to 1.8V only (1.826V when measured on the board), just a portion of the pullable range will be available. Additionally, the midpoint of the modulation will be offset in frequency due to this as well. The table above shows calculated offsets from a programmed carrier frequency of 144.8MHz at a specific pull setting and DAC output voltages. I made a choice of 38 ppm pull for the actual transmissions which was based on desired peak deviation of 3.0kHz of the 2200Hz tone and 1.65kHz of the 1200Hz tone. More details on the peak deviations in APRS transmissions again in the previously link article. The 2200Hz lookup table ranges in values from 0 to 4095 (12-bit DAC) while the 1200Hz lookup table is appropriately scaled. When devising the offset for the programmed frequency, I had to take into account not only the value at 0.913V from the table above, but also include additional fixed offset which originated in the fact that this specific TT7B board was equipped with a VCXO version of the TCXO and its voltage control pin was tied to ground. According to the datasheet, that should pull its output frequency by -5ppm which would at 144.8MHz add further 724Hz to the total offset.

| Area | F [MHz] | FVCO [MHz] | Offset [Hz] |

|---|---|---|---|

| North America | 144.390 | 866.340 | -3920 |

| New Zealand | 144.575 | 867.450 | -3890 |

| S. Korea | 144.620 | 867.720 | -3880 |

| China | 144.640 | 867.840 | -3880 |

| Japan | 144.660 | 867.960 | -3885 |

| Europe, Russia | 144.800 | 868.800 | -3855 |

| Argentina, Uruguay | 144.930 | 869.580 | -3940 |

| Venezuela | 145.010 | 870.060 | -3920 |

| Australia | 145.175 | 871.050 | -3990 |

| Thailand | 145.525 | 873.150 | -3910 |

| Brazil | 145.570 | 873.420 | -3910 |

Prior to each transmission, the Si5351B is programmed to a specific frequency. For the sake of simplicity, the code focuses on programming the VCO frequency which is then always divided by an integer divider of 6 to get the desired output. This approach works fine for all 2m band APRS frequencies, but for any output below 100MHz the code would have to be modified. The last column in the table contains actual measured offsets of midpoints of modulation at individual APRS frequencies. They are several hundred hertz larger than the previously calculated values and slightly differ frequency to frequency. Since the differences aren't that large, a fixed offset of 3900Hz is automatically added when a new frequency is programmed to the Si5351B.

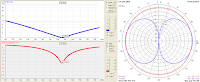

Since my oscilloscope tops out way below the APRS frequencies, I transmitted a couple of test packets directly to an RTL-SDR input through a 30dB attenuator, and recorded the demodulated audio with SDR#. The following screengrabs show the recordings in Audacity.

The frequency analysis of a couple of test packets shows much cleaner spectrums than in case of my previous APRS transmissions from TT7F which tried to replicate the AFSK modulation in two different ways. First using conveniently timed GFSK modulation, second a much less refined lookup table approach. Here on TT7B, there seems to be very little difference comparing the 16 element lookup table on the left to the 32 element lookup table on the right.

These are the actual recordings, the 16 element table with main clock at 16MHz at the top, and the 32 element table running at 25MHz at the bottom. Both .wav files can be downloaded here: 16 element and here: 32 element.

DireWolf decodes the test packet without bit corrections, reports an adequate audio level ratio between the tones (11 - 1200hz, 18 - 2200Hz), and manages to decode the packet with six out of nine decoders which correspond to gains for the 2200Hz tone of -6.0dB to +5.3dB as more in detail described in the DireWolf's documentation.

Encoding

As mentioned previously, the task of the tracker is to deliver back as much information about the balloon itself and its surrounding conditions as possible. For that, the tracker will use the worldwide APRS network of iGates and digipeaters. Although the APRS protocol supports sending telemetry along positional information and can even graph the data, the amount of data is limited. To send all the data I wanted, I decided to define my own packet structure, use the APRS network to only collect the data packets, and do the decoding manually. The position of the balloon will still be plotted online on a map such as aprs.fi, but all the telemetry data will be reported encoded in the comment section of the APRS packet.

| !/5LD\S*,yON2WYm%=,)ZiLx,f:-D33ZM0!<QU |

|---|

| !/5LD\S*,yON2WYm%=,)ZiLx,f:-D33ZM0!<QU5N^JS%<z!(Z/'T$r7U@#]KRj1F(!9T,wQ7,8Z |

|---|

An example of the packet TT7B will be sending can be seen above. The first is a shorter packet containing only current information, while the second is a full length packet containing current information and an additional backlog of data acquired previously during the flight. This is used to provide information about the balloon's whereabouts for when it was outside of reception range. The shorter packet is 38 bytes long plus additional 39 bytes of flags, paths and crc. The full length packet is 75 bytes plus again the additional 39 bytes. It takes 513ms in total to transmit the 77 bytes of the shorter packet, and 760ms to transmit the 114 byte packet.

| Byte | Symbol | Description | Decoded |

|---|---|---|---|

| 0 | ! | Data Type Identifier | |

| 1 | / | Symbol Table Identifier | |

| 2:5 | 5LD\ | Latitude | 49.49148° |

| 6:9 | S*,y | Longitude | 18.22311° |

| 10 | O | Symbol Code (Balloon) | |

| 11:12 | N2 | Altitude (coarse) | 1127.42m |

| 13 | W | Compression Type Identifier |

The first 14 bytes of the packet constitute a standardized compressed position report as described in APRS Protocol Reference 1.0.1. Latitude and longitude can be decoded using these equations: $$Latitude=90-((c_1-33)\times 91^3+(c_2-33)\times 91^2+(c_3-33)\times 91+(c_4-33))/380926$$ $$Longitude=-180+((c_1-33)\times 91^3+(c_2-33)\times 91^2+(c_3-33)\times 91+(c_4-33))/190463$$ where $c_{1..4}$ represent individual chars $5LD\setminus$ for latitude and $S*,y$ for longitude. Following the same char representation, altitude in meters can be decoded using this equation: $$Altitude=1.002^{(c_1-33)\times 91+(c_2-33)}/3.28084$$ The compression and decompression introduce some amount of error in the original values. In case of latitude, the resolution can be down to 29cm, while in case of longitude down to 59cm which corresponds to higher accuracy then most GPS modules can achieve. However in case of altitude, the potential error increases with the altitude itself. At 12,000m it can be up to 24m, at 40,000m it can be up to 80m. For this reason, there is additional correction data transmitted among the data in the remainder of the packet to report altitude data within 1m of the measured value. Note that these errors originate purely in the compression process and do not say anything about the accuracy of the positional fix itself.

| Byte | Symbol | Description | Decoded |

|---|---|---|---|

| 14:15 | Ym | Temperature MCU | 23.44°C |

| 16:17 | %= | Temperature THERMISTOR_1 | 23.74°C |

| 18:19 | ,) | Temperature THERMISTOR_2 | 0.01°C |

| 20:21 | Zi | Temperature MS5607_1 | 25.18°C |

| 22:23 | Lx | Temperature MS5607_2 | 0.00°C |

| 24:26 | ,f: | Pressure MS5607_1 | 97395Pa |

| 27:29 | -D3 | Pressure MS5607_2 | 102575Pa |

| 30:31 | 3Z | Battery Voltage | 1.512V |

| 32:33 | M0 | Ambient Light | 22.10lux |

| 34:37 | !<QU | Altitude (offset: 0-99m), Satellites, Active Time, Last Reset |

This portion of the packet contains the current telemetry data. All individual data points in some form utilize Base91 encoding to transform their original value to an ASCII character representation that is transmittable via APRS. The thermistor one and two temperatures, and battery voltage are all raw ADC readings (0-4095) Base91 encoded into two ASCII characters. The following equation is common to all of them: $$ADC_{raw}=(c_1-33)\cdot 91+(c_2-33)$$ After acquiring the raw ADC values, the calculations differ. To get the temperature measured by a thermistor in °C, first calculate the voltage the raw ADC value represents. This voltage is across the thermistor itself in a voltage divider setup and allows to calculate the thermistor's resistance. The resistance then plugs into a Steinhart-Hart equation where $R_2$ is the resistance at temperature $T_{therm}$. The coefficients $a$, $b$ and $c$ were determined earlier for this specific thermistor. $$V_{R2}=\frac{ADC_{raw}}{4095}\cdot 1.826V$$ $$R_{2}=\frac{V_{R2} \cdot 49900\Omega}{1.826V - V_{R2}}$$ $$T_{therm}=\frac{1}{0.00128424+0.00023629\cdot ln(R_{2})+0.0000000928\cdot ln(R_{2})^3}-273.15$$ The battery voltage in volts can be calculated by following this equation. The factor of 2 comes from the fact that the measurement is done after a voltage divider. $$V_{batt}=\frac{ADC_{raw}}{4095}\cdot 1.826V\cdot 2$$ The MCU and the two MS5607 temperature readings follow the same decoding process. First decode the Base91 encoded value $n$. Then subtract an offset of 4000 from $n$ and divide the result by 50 to get the actual temperature in °C. $$n=(c_1-33)\cdot 91+(c_2-33)$$ $$T=\frac{n-4000}{50}$$ In case of the two pressure values, all that needs to be done is to decode the three Base91 encoded characters. The result is a pressure value in Pa. $$P=(c_1-33)\cdot 91^2+(c_2-33)\cdot 91+(c_3-33)$$ The ambient light readings produced by the sensor can span from 0.0072 to 120,000lux. To preserve resolution at even the very low end of the range and not waste too many characters in transmitting these values, I decided to utilize a similar approach as is used in the original APRS format to compressed altitude. The consequential decrease in resolution at the higher end of the range of possible values doesn't matter that much here. The following equations result in an illuminance reading in lux. $$n=(c_1-33)\cdot 91+(c_2-33)$$ $$E_v=\frac{10^{n\cdot log(1.002)}}{139}$$ The last four characters of this section of the packet encode a few different values together. First decode the Base91 encoding to a single number. $$n=(c_1-33)\cdot 91^3 + (c_2-33)\cdot 91^2+(c_3-33)\cdot 91+(c_4-33)$$ Last Reset is a number between 0 and 5 corresponding to the source of the last reset as reported by the microcontroller in register RCAUSE. The sources are: 0 - NONE no reset source; 1 - POR power on reset; 2 - BOD brown out detector; 3 - EXT external; 4 - WDT watchdog timer; 5 - SYS system reset. To get the value use the following equation. $$reset=n\; mod\; 6$$ Active Time is the time measured by the onboard Real-Time Counter between waking up from standby mode to construction of the APRS packet, so the actual transmission of 0.5-0.7s is excluded. The point of this measurement is to get information on the time to first fix of the GPS module. The resolution is 0.1s. $$t=\bigg(\bigg\lfloor\frac{n}{6}\bigg\rfloor\; mod\;1000\bigg)/10$$ The next value to extract is the number of satellites used in the GPS positional fix. To get the number follow this equation. $$sats=\bigg(\bigg\lfloor\frac{n}{6\cdot 1000}\bigg\rfloor\; mod\;17\bigg)$$ As mentioned earlier, the compression and decompression used when transmitting altitude data introduces an error. To compensate for this error, Altitude Offset is added to Altitude Coarse rounded down to nearest integer. The following equation reveals how to arrive at the value. $$alt=\bigg\lfloor\frac{n}{6\cdot 1000\cdot 17}\bigg\rfloor$$ In this example !<QU decodes as: Last Reset = 1; Active Time = 0.1s; Satellites = 4; Altitude Offset = 2m which when added to Altitude Coarse gives an altitude of 1129m reported by the GPS module. This collective encoding is used in a couple of instances in the following backlog section as well.

| Byte | Symbol | Description | Decoded |

|---|---|---|---|

| 38:41 | 5N^J | Backlog: Latitude | 49.44184° |

| 42:45 | S%<z | Backlog: Longitude | 18.01337° |

| 46:49 | !(Z/ | Backlog: Altitude (precise: 0-50,000m), Satellites, Last Reset | |

| 50:54 | 'T$r7 | Backlog: Year, Month, Day, Hour, Minute, Active Time | |

| 55:56 | U@ | Backlog: Temperature MCU | 15.26°C |

| 57:58 | #] | Backlog: Temperature THERMISTOR_1 | 35.99°C |

| 59:60 | KR | Backlog: Temperature THERMISTOR_2 | -62.65°C |

| 61:62 | j1 | Backlog: Temperature MS5607_1 | 53.18°C |

| 63:64 | F( | Backlog: Temperature MS5607_2 | -12.52°C |

| 65:67 | !9T | Backlog: Pressure MS5607_1 | 2235Pa |

| 68:70 | ,wQ | Backlog: Pressure MS5607_2 | 98965Pa |

| 71:72 | 7, | Backlog: Battery Voltage | 1.795V |

| 73:74 | 8Z | Backlog: Ambient Light | 0.5279lux |

This last portion of the APRS packet contains the optional backlog. Most of the data such as latitude, longitude, MCU, thermistor and MS5607 temperatures, MS5607 pressure, battery voltage, and ambient light are encoded in the same way as in the current data section. The bytes 46 to 49 collectively represent encoded altitude (this time without encoding error), the number of satellites and information about the last reset source. The process once again starts with decoding the Base91 representation. $$n=(c_1-33)\cdot 91^3 + (c_2-33)\cdot 91^2+(c_3-33)\cdot 91+(c_4-33)$$ Extracting the Last Reset value follows the same steps as previously. $$reset=n\; mod\; 6$$ Getting the number of Satellites is slightly different to previously. $$sats=\bigg(\bigg\lfloor\frac{n}{6}\bigg\rfloor\; mod\;17\bigg)$$ And the precise Altitude is arrived at by following this equation. $$alt=\bigg\lfloor\frac{n}{6\cdot 17}\bigg\rfloor$$ In this example !(Z/ decodes as: Last Reset = 0; Satellites = 5; Altitude Precise = 619m.

The remaining bytes 50 to 54 collectively represent encoded year, month, day, hour, minute and active time of the backlogged telemetry. Since there are five Base91 encoded bytes this time, the first step is slightly different. $$n=(c_1-33)\cdot 91^4+(c_2-33)\cdot 91^3+(c_3-33)\cdot 91^2+(c_4-33)\cdot 91+(c_5-33)$$ First the Active Time is extracted in this way. $$t=\frac{n\; mod\; 1000}{10}$$ Followed by the Minute. $$min=\bigg(\bigg\lfloor\frac{n}{1000}\bigg\rfloor\; mod\;60\bigg)$$ Then the Hour. $$hour=\bigg(\bigg\lfloor\frac{n}{1000\cdot 60}\bigg\rfloor\; mod\;24\bigg)$$ And the Day. $$day=\bigg(\bigg\lfloor\frac{n}{1000\cdot 60\cdot 24}\bigg\rfloor\; mod\;31\bigg)+1$$ The Month. $$month=\bigg(\bigg\lfloor\frac{n}{1000\cdot 60\cdot 24\cdot 31}\bigg\rfloor\; mod\;12\bigg)+1$$ And lastly the Year. $$year=\bigg\lfloor\frac{n}{1000\cdot 60\cdot 24\cdot 31\cdot 12}\bigg\rfloor +2018$$ In this specific example 'T$r7 decodes as: Active Time = 12.3s; Minute = 34; Hour = 10; Day = 3; Month = 11; Year = 2018.

I've written a few Python scripts to help with the decoding. First is a GUI for quickly decoding a single packet as shown in the screengrabs above. Then a piece of code that grabs and parses packets collected at aprs.fi. And lastly a decoder that takes the packets grabbed from aprs.fi and decodes them to a .csv file. All can be found in the Accessories folder in TT7B's main Github repository.

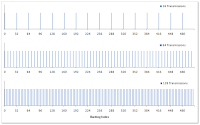

Every nth instance of the current positional and telemetry data is stored in the microcontroller's non-volatile memory (NVM) which retains this information even in case of a power down or a reset. The memory, which also contains the main code instructions, is organized into 64 byte pages. In case of SAML21E17, that is 131,072 bytes in 2048 pages. Since the code I've written for the tracker took up less than 50% of the overall memory, it left me with the other half for potential data storage. In the end, I decided to use 512 pages from the last quarter of the memory to each hold one backlog. The targeted part of memory must be erased prior to writing in it. The NVM Controller erases by whole rows which each contains four pages. Each row can then be written four times - every page once. When constructing an APRS packet, the microcontroller checks an address in the backlog allocated memory, and if it finds an already written log, it appends it to the packet. The way in which it chooses a backlog to transmit is according to a Van Der Corput Sequence (another inspiration from the UBSEDS flights). The chart above illustrates this sequence after 16, 64, and 128 transmissions. Contrary to a simple ascending/descending sequence, it quickly provides an overview of the whole extent of the backlog, and then evenly fills in the blanks with additional transmissions.

GPS

Since the GPS module is the most power hungry individual part on the tracker, the main goal was to find the right compromise between power consumption and positional accuracy of its measurements. The ZOE-M8B's datasheet states a horizontal position accuracy of 2.5m when the receiver is in Continuous mode, 3.0m when in Super-E Performance mode, and 3.5m in Super-E Power Save mode for positional solutions based on signals from the GPS constellation alone. The module can also utilize the GLONASS, BeiDou and Galileo GNSS systems, or their combination with less accuracy (according to the datasheet values) and more power consumed. The accuracy is stated in Circular Error Probable (CEP) figures specified over a 24 hour period with the receiver being locked on to 6 or more satellites at signal levels of -130dBm. The Continuous mode figure, for example, means that 50% of position measurements over the specified period were somewhere within a circle 2.5m in radius centered at the real position, while the remaining 50% lay an unspecified distance outside that circle. The datasheet didn't provide any figures on vertical accuracy.

It should be noted that these figures were achieved with ideal conditions as specified. Real life positional measurements are often scattered around a bit more depending on the actual environment. The typically mentioned sources of error are inaccuracies in satellite clock and orbit, deviations of the real conditions from the receiver's ionospheric and tropospheric models, the receiver measuring reflected signals instead of direct signals (multipath), or the actual geometry of the satellite constellation (often expressed as various Dilution Of Precision (DOP) values). The Essentials of Satellite Navigation document, which can be found on u-blox's website, discusses the matter in more detail and is a useful source of information on GPS operation in general. In case of doing accuracy tests in real life environments, the multipath error and the actual geometry of satellites used in the solution will most likely be the main variables compared to the ideal conditions case.

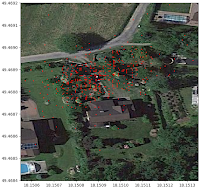

The tests that collected data with TT7B on the GPS module's accuracy that follow were done in my garden where the tracker had a reasonable view of the sky, though as the photographs document not all the way to the horizon. The nearby trees could have possibly contributed to signal reflections as well.

The first plot shows the u-blox module in the default Super-E Performance mode receiving signals from the GPS and GLONASS constellations. The tracker repeatedly polled the UBX-NAV-PVT message until it returned a solution with a valid fix (gnssFixOk flag) and 4 or more satellites. It then proceeded to transmit an APRS packet, wait 2 seconds, and repeat the cycle again. The GPS module was continually supplied in the first four tests. In each test, I had the tracker collect data like this for an hour. In an attempt to minimize the number of variables, the tests were done one a day, always starting at the time the GPS satellites were in the same position in the sky. The orbits of the GPS constellation are such that the positions of the satellites above one place repeat once per sidereal day, every 23 hours and 56 minutes. Other variables such as ionosperic and tropospheric delays, satellite ephemeris and clock errors, though, remained. The second plot shows the module in a higher consumption Continuous mode receiving only GPS satellites. The white dot designates the average position.

In the third plot, the module was set to the Continuous mode (UBX-CFG-RXM message) again, and configured to receive GPS, GLONASS, and Galileo satellites (UBX-CFG-GNSS message). The resulting plot, however, is most likely composed of measurements on the GPS satellite signals only as further discussed later. The fourth plot then shows the module in the Continuous mode receiving GPS and SBAS satellites. The red dots denote GPS only solutions, while the blue dots solutions with applied corrections after the module locked on to an SBAS satellite (diffSoln flag in UBX-NAV-PVT).

In the following plots, the u-blox module is no longer supplied continually, but the power switch to the module is turned off, and the MCU is commanded to low power standby mode during the 2 second wait period. As a result, the module is forced to undergo a hot start and re-lock on to the satellites in view. The module retains information about the current time and satellite positions during the power-off period, because its battery-backed memory and RTC clock are continually supplied through VBCKP. According to the datasheet, the minimum signal levels for hot starting the module are 17.0dBHz in case of the GPS satellites. Although, the datasheet values for sensitivity are said to be 'demonstrated with a good external LNA'. Aside from the conditions just described, the module in the fifth plot was in the Continuous mode receiving GPS satellites and required a solution with at least four satellites and a valid lock. In case of the sixth plot, the settings only differed in requiring at least 6 satellites in a solution.

With the seventh plot, the module was set up the same way as previously, except now it calculated and output a new solution every 250ms (default rate is 1Hz, 2Hz during acquisition, configurable via UBX-CFG-RATE). Setting a higher navigation rate is said to improve accuracy in Super-E mode. I couldn't, however, find any information about a potential impact on accuracy nor the time to first fix during hot starts for when the module is in Continuous mode. At a minimum, though, the 4Hz rate should shorten the time by 0 to 750ms depending on when inside a second the receiver obtains the first valid solution. The eighth plot shows the module in Continuous mode receiving GPS satellites and outputting solutions at a 4Hz rate, this time requiring 7 satellites for a valid solution.

| Settings | 3Dmed | 3Davg | 3Dmax | Hmed | Havg | Hmax | Vmed | Vavg | Vmax |

|---|---|---|---|---|---|---|---|---|---|

| Super-E, GPS, GLONASS | 11.9m | 14.4m | 53.9m | 7.8m | 9.0m | 37.7m | 7.3m | 10.0m | 47.3m |

| Continuous, GPS | 6.6m | 7.4m | 27.7m | 3.1m | 3.7m | 16.9m | 5.4m | 5.9m | 24.4m |

| Continuous, GPS, GLONASS, Galileo | 7.8m | 9.3m | 38.0m | 4.8m | 5.3m | 25.3m | 5.6m | 7.0m | 33.6m |

| Continuous, GPS, SBAS | 4.6m | 5.1m | 29.5m | 2.6m | 2.8m | 11.9m | 3.2m | 3.8m | 27.2m |

| Continuous, GPS, 4 sats, standby | 27.5m | 33.2m | 294.3m | 17.6m | 22.6m | 226.5m | 14.2m | 20.5m | 187.8m |

| Continuous, GPS, 6 sats, standby | 23.3m | 28.0m | 113.8m | 12.2m | 14.4m | 72.6m | 16.3m | 22.0m | 109.3m |

| Continuous, GPS, 6 sats, 4Hz, standby | 17.6m | 20.1m | 91.0m | 9.4m | 10.5m | 43.2m | 12.3m | 15.5m | 83.3m |

| Continuous, GPS, 7 sats, 4Hz, standby | 18.6m | 21.4m | 67.2m | 9.9m | 11.2m | 45.0m | 13.1m | 16.6m | 62.1m |

This table summarizes the previous data in actual numbers. The median, average and maximum deviations in three-dimensions, horizontally and vertically are referenced to the average position of the dataset (marked by the white dot). Immediately, it is apparent that when the u-blox module is supplied continually and thus allowed to track and acquire satellites without interruptions, the accuracy is much better. The Super-E mode, which is a module controlled power saving operation, results in higher deviations than when the module runs full power in Continuous mode. Concerning GLONASS, Galileo and BeiDou, there is a further discussion on these constellations a little later. Having the module receive SBAS satellites improves the accuracy slightly, it is, however, unusable for discontinuous supply operation where the time to first valid fix is critical as the SBAS satellites require longer times to get incorporated in the positional solutions. When the module is regularly brought in and out of hardware backup mode by cutting and restoring the main supply, it every time undergoes a hot start during which it has to re-lock onto satellites. Provided the backup period is short enough (less than 4 hours), and the module is able to track time with an external RTC, it can use the time and previously acquired orbital data now stored in its battery backed RAM to quickly search much smaller frequency/timeshift space and re-synchronize with the known satellite signals. The table shows that waiting for a solution based on more satellite signals increases accuracy, though, it for some reason doesn't come close to accuracy of a continually supplied receiver.

During the tests, I had the MCU measure the time between powering the u-blox module up and the module returning a valid solution according to my requirements. This duration was then transmitted in each APRS packet. The collected values for individual datasets are plotted in the chart above. From the data, it seems that increasing the navigation rate to 4Hz had the largest impact on shortening the active time. The number of satellites, on the other hand, didn't seem to impact active time that much, so its advantage lies mainly in increasing accuracy. Occasional prolonged active times are expected in this manual power saving approach as the module will eventually need to update the ephemerides of individual satellites, or search for a new one when a tracked satellite disappears below horizon, by decoding currently transmitted navigation messages which takes additional time (18-36s for a GPS satellite's ephemeris). The minimum recorded active time of 1.6s, on the other hand, shows that when the receiver has all ephemerides fresh and tracks strong signals from a sufficient number of satellites, it can produce a valid solution in a very short time. Given the tests were done on the ground in an unideal environment, I would expect the average active time to further decrease when the tracker is at altitude hanging underneath a balloon.

In an attempt to look closer at the difference in accuracy of the continually powered versus controlled power supply datasets, I did another test where I had the u-blox module receiving only GPS signals and doing measurements at a 10Hz rate. The MCU would repeatedly poll UBX-NAV-PVT until it returned a solution based on 7 satellites (numSV) with a valid fix (gnssFixOk). It would then transmit an APRS packet, wait for 2 seconds, and repeat the cycle again. Overall, one complete cycle typically took 3 seconds. The MCU would count the cycles and after each 30th cycle, it would cut the main power supply to the u-blox module, after 2 seconds it would restore it, and it would continue in the poll-transmit-wait cycle once again. The chart above then shows the median, average and maximum deviations with respect to the average position of the whole dataset for specific durations since the u-blox module was brought back from the hardware backup state (no main supply, 1.8V at VBCKP). The data show that indeed the first valid solutions after a hot start deviate more from the actual position and that the deviations decrease longer the module is continually powered. Waiting for a specific number of satellites in a navigation solution alone is then not in itself sufficient to achieve the same average accuracy as with a continually powered module.

| GNSS | Earth [dBW] | C/N0 [dBHz] | Cold [dBHz] | Hot [dBHz] | Track [dBHz] |

|---|---|---|---|---|---|

| GPS | -158.5 | 45.5 | 26.0 | 17.0 | 8.0 |

| GLONASS | -161.0 | 43.0 | 30.0 | 20.0 | 8.0 |

| BeiDou | -163.0 | 41.0 | 31.0 | 19.0 | 14.0 |

| Galileo | -157.0 | 47.0 | 36.0 | 23.0 | 15.0 |

By changing the settings in the UBX-CFG-GNSS message, I also tested GLONASS only, Galileo only, and BeiDou only reception. However, neither setting managed to get a valid fix in under 20 minutes. After a more detailed examination, I found that the UBX-NAV-SAT message never reported any GLONASS, Galileo, nor BeiDou satellites with 'acquired signal', only a few flagged as 'searching signal'. A web-based GNSS constellation viewer was showing plenty of satellites in the sky during that time. The table above summarizes minimum signal power levels in dBW expected at the surface of Earth for individual systems and corresponding Carrier to Noise ratios (C/N0) in dBHz at noise power density of -204dBW/Hz. The latter three columns then contain minimum signal levels needed during a receiver cold start, hot start, and tracking phases derived from the receiver's sensitivity values for continuous mode stated in the datasheet. Although, signal levels too close to the minimum values will lead to longer acquisition times as the probability of an error in decoding the navigation message increases. Values in the range of 32 to 36dBHz are typically mentioned for a reliable GPS navigation data acquisition. It is apparent from the table that the ZOE-M8B receiver is most suited for the GPS signals, while the other systems require better signal conditions. It is thus possible that the design of the PCB with a simple ceramic chip antenna on TT7B is not sufficient for the other constellations. At least not in the environment where I tested it.

The W3011A antenna is stated to be intended for the GPS L1 band centered on 1575.42MHz. Although, the ground clearance area was designed according to specification in the datasheet, the typical performance was characterized on a 80x37mm test board which is a bit larger than the dimensions of TT7B. Due to all the traces and its shape, the tracker board won't most likely work as too good a ground plane for the chip antenna either. Nevertheless, in principle the antenna's radiation pattern when oriented as in the images above should resemble a vertical dipole's pattern with the gain more or less evenly distributed towards the horizon - the XY plane in the diagram above taken from the datasheet. A further hindrance to the GLONASS and BeiDou signals could be the fact that their frequency ranges are at the edges of the antenna's specification. Although, that wouldn't explain the lack of signals from the Galileo system as it is centered on the same frequency as GPS.

The chart above is an example of satellite signal strengths in dBHz as reported by the UBX-NAV-SAT message (C/N0 carrier to noise ratio) right after the module produced a valid solution. Each curve shows the number of satellites at the time within a specific signal strength range. The black curve then corresponds to the number of satellites used in producing the navigation solution as reported in UBX-NAV-PVT message (numSV). The three datasets were obtained during the previous hour long tests. Specifically, the top data come from when the module was being manually powered on and off, receiving only the GPS constellation, and requiring 4 satellites for a valid solution. The middle dataset was the same setup but requiring 7 satellites and running at a 4Hz rate. During the bottom dataset, the module operated continually without any power down periods, while it was receiving only the GPS constellation. No signal strength above 40dBHz was ever recorded with this antenna setup in this environment in any of the power modes.

These charts show current consumption measurements of the TT7B tracker for when the u-blox module transitioned to tracking state after initial satellite acquisition. In case of the top left chart depicting the default Super-E Performance mode, the module transitioned to power-optimized tracking state. The measurements almost entirely represent consumption of the u-blox module. The only simultaneously powered IC on the board was the MCU with its consumption of about 230μA at 1.826V. The step between two data points was 12ms. The average consumption of the Super-E mode was 13.4mA. The remaining three charts show the module in the Continuous mode receiving only GPS satellites, and differ in the measurement rate. The average consumption for the 1Hz, 4Hz, and 10Hz case was 30.9mA, 33.7mA, and 34.4mA, respectively. Based on the data, there seemed to be regular temporary increase in consumption every 10 seconds.

This is what the current consumption profile looks like when the main power supply to the u-blox module is controlled externally. In both examples, the module had previously acquired ephemerides from a sufficient number of satellites, had produced a valid navigation solution, and had been set to hardware backup mode by removing its main power supply. The charts then show the moments the main power supply was restored and the MCU started to poll UBX-NAV-PVT message. Once a valid solution with a required number of satellites was obtained, the main power supply was removed again. During the first half a second the module does some initialization during which the datasheet suggests to wait before attempting UART communication. Following that, the module re-locks onto the known satellites. I am guessing that that is what was happening during the quick succession of peaks in consumption. In the first example, the module then started producing quick spikes in consumption in 1 second intervals corresponding to the 1Hz measurement rate. In the second example, the module first produced 2 current spikes per second suggesting it had to transition to the acquisition state before it could switch to the 1Hz tracking state as well. In the first case, it took the module 5 seconds of active time to produce a valid solution at a 32.5mA average consumption, while in the second it was 8 seconds at 35.3mA.

When the module is configured to receive signals from GLONASS, or BeiDou constellations alongside GPS or Galileo, the consumption increases, because the module has to power up a second RF front-end as the satellites transmit in different frequency bands. The chart above shows the module's current consumption during the first 18 seconds after power-up. In one case (blue line), the module was set to receive only GPS satellites. In the other case (red line), it was set to receive the GPS, GLONASS and Galileo constellations concurrently. The average consumption during this acquisition phase was 38.8mA versus 47.9mA.

In short, the previous findings can be summarized as less power consumed, less accurate measurements. Given the tracker will be battery powered and accuracy approaching the datasheet values comes only with prolonged active times, saving power will be prioritized at the cost of larger average deviations in the reported positions. Thus, I don't expect to be able to follow subtle variations in altitude very closely that could in principle be linked to variations in temperature and pressure measured be the other sensors. The actual control of the module will constitute having it receive only GPS satellites (and QZSS satellites as recommended in the datasheet), setting the measurement rate to 10Hz to shorten the active time, externally controlling the main power supply thus forcing the module to hardware backup mode, and switching the module to the Continuous mode to leave it in acquisition or tracking states during wake-up periods.

In terms of the code, the functions to enable or disable the main power supply to the u-blox module can be found in the PORT library operating the I/O Pin Controller. The communication between the MCU and the module is serviced by functions in another SERCOM library this time dedicated to the Universal Synchronous and Asynchronous Receiver and Transmitter (USART). The default baud rate the module expects is 9600 which can be increased to 115200 baud, for example. This shortens the transmission time of a 100 byte UBX-NAV-PVT message from 104ms to less than 9ms. All functions written to modify various settings, poll desired messages, and parse the received responses can be found in the ZOE_M8B library.

A centimeter positional accuracy is possible with GPS, however, it belongs to the scope of more advanced and expensive technologies. Differential GNSS (DGNSS, DGPS) techniques achieve higher accuracy by having a stationary reference receiver calculate and transmit corrections for the signals from individual satellites. These are then received and applied to measurements by mobile receivers. This approach is, however, limited by the required proximity to the reference station. Real Time Kinematics (RTK) further increases accuracy by employing carrier phase measurements on top of the base station-rover setup as opposed to just measurements of the slower pseudorandom code's chips. The NEO-M8P module by u-blox is one example that supports this functionality. Another technique that increases accuracy is employed in dual band receivers such as the ZED-F9P. These modules are able to correct for the ionosperic delay by receiving two different frequency signals from one satellite (L1C/A and L2C for example), and from the measured difference in arrival time correct the error caused by the ionosphere. In case of ZOE-M8B and TT7B, it is realistic to expect accuracy in ranges as detailed in the tests above, or potentially slightly improved by the unobstructed view of sky at altitude and the lack of multipath error under a balloon.

External Sensors

The MCU's temperature sensor, the ambient light sensor (VEML6030), and one pressure/temperature sensor (MS5607) were already populated on the tracker after reflow. The remaining sensors - the onboard thermistor, the external thermistor, and the external pressure/temperature sensor - had to be added separately.

The onboard thermistor's thin leads fit inside two larger vias right next to the MCU. Thanks to their length, the bead itself can be up to 50 mm away from the board. The purpose of this thermistor is to measure the ambient air temperature.

The external pressure sensor, intended to be inside a balloon, required some fine tip soldering. First, a 0402 100nF decoupling capacitor had to be soldered between VDD and GND pins. Then six 0.118mm magnet wire strands were soldered to individual pins.

Similarly, two strands were soldered to the external thermistor's shortened leads. All these wires were first twisted in pairs, then the pairs themselves were twisted together to form a single strand that would extend to inside a balloon. The twisted nature of the two thermistor's wires should limit any potential interference to the analog measurement from the neighboring SPI lines. Alternatively, the software may ensure the SPI interface is idle during a measurement on the thermistor.

The individual wires were soldered to their respective pads on the backside of the tracker. The magnet wire is coated in a layer of polymeric insulation which is removed by the heat of a soldering iron when being soldered to the pad.

Based on the performance of my previous superpressure balloons, the tracker is expected to operate at altitudes between 10,000 to 13,000 meters. This range corresponds to 264 to 165hPa pressure and -50.0 to -56.5°C temperature levels according to the Standard Atmosphere model. A cursory review of historical data from atmospheric soundings suggests that ambient air temperature could in reality easily range from -40 to -72°C (January and August 2018 extremes), while a pressure level ascends and descends within roughly a 1000m range throughout a year. These specific values come only from my closest weather station in Prostejov, CZ. If the whole world, all seasons of the year, and all weather patterns were taken into account, the stated ranges could further expand.

| Sensor | Min | Max | Resolution | Accuracy | Unit | Note |

|---|---|---|---|---|---|---|

| MCU | -40.0 | +85.0 | 0.12 | -8/+9 | °C | T > 0°C |

| -12/+14 | °C | T < 0°C | ||||

| Thermistor | -80.0 | +150.0 | <0.1 | -1/+1 | °C | 0 to +70°C (acc.), -70 to +34°C (res.) |

| MS5607_T | -40.0 | +85.0 | 0.002 | -2/+2 | °C | -20 to 85°C |

| -4/+4 | °C | -40 to 85°C | ||||

| MS5607_P | 30,000 | 110,000 | 2.4 | -200/+200 | Pa | 0 to +50°C and 300 to 1100hPa |

| 30,000 | 110,000 | 2.4 | -350/+350 | Pa | -20 to +85°C and 300 to 1100hPa | |

| 1,000 | 120,000 | 2.4 | Pa | Linear Range of ADC | ||

| VEML6030 | 0.0072 | 120,000 | 0.0036 | lx | 0.0036 to 236lx (max. res.) | |

| 1.8432 | lx | 1.8432 to 120,000lx (min. res.) |

This table summarizes available parameters of individual sensors as stated in their datasheets. The MCU's internal temperature sensor is the least accurate, and it is included just out of interest and for comparison to its more accurate companions. There weren't any details about the type of the sensor in SAML21's datasheet. Internal temperature sensors in other microcontrollers that I could find some information about typically utilize a diode or a pair of transistors with different junction areas to produce a temperature dependent voltage (Wikipedia description) which is then sampled by the MCU's ADC. On SAML21, the temperature sensor output is wired to ADC's input channel 24. The code side of things slightly differs from normal ADC sampling mainly in setting the MCU and ADC to specific clock speeds, sampling time and reference - all detailed in Table 46-34 in the datasheet. The calculation of actual temperature (also detailed in the datasheet) then requires accessing and utilizing the sensor's factory calibration data stored at a specific address in the microcontroller's NVM Temperature Log Row.

The PX502J2 thermistor's datasheet states accuracy of +-1°C but only for a 0 to +70°C range. There isn't any further information about the rest of the operating range. The datasheet provides a resistance vs. temperature table of values spanning from -55 to +150°C which served to derive Steinhart-Hart coefficients to be used in calculating the actual temperature from the raw ADC measurement. The resulting curve of the Steinhart-Hart equation which approximates the relationship between resistance and temperature deviates by -0.14 to +0.07°C in a +50 to +150°C range and only by -0.0068 to 0.0005°C in a -55 to +50°C range at most from the table values, while it further extends to the advertized lower extreme of the operating range at -80°C. Another potential source of error could come from the tolerance of the voltage divider's R1 resistor of which the thermistor is a part. Assuming the 0.5% R1 was at the edge of its tolerance range, this would introduce a 0.055°C error at -80°C, a 0.1°C error at 0°C and a 0.22°C error at +150°C compared to a precise 49900Ω resistor. The resolution of the measurement the setup provides stays better than 0.1°C in a -70 to +34°C range with a maximum resolution of 0.02°C at around -24°C. Aside from a function enabling power to the sensor circuit, all code can be found in the ADC library. When the ADC is enabled, factory calibration values for the ADC's linearity and bias are fetched from an address in the MCU's NVM Software Calibration Area and forwarded to respective registers. The same voltage is used to supply the thermistor circuit and provide reference to the ADC (VDDANA) thus eliminating any potential error arising from unstable supply. It is possible to setup the ADC to automatically average a number of 12-bit measurements, or oversample and decimate the measurements to obtain a 16-bit result. The 1.4μs time constant of the ADC input should be taken into account when selecting the ADC clock frequency with a measurement taking up 13 clock cycles.

The MS5607 sensor module, as the datasheet says, includes a piezo-resistive pressure sensor and a 24-bit ADC with factory calibrated coefficients. More details about the structure of the module and how exactly temperature impacts the pressure measurement can be found in this document - 'Temperature Compensation for MEAS Pressure Sensors'. The module provides a 24-bit digital value representing an uncompensated analog output of the sensor and another 24-bit value representing the temperature of the sensor. Both values along with the factory calibrated coefficients are necessary for computing the actual pressure and temperature in Pascal and degree Celsius. The accuracy of the temperature measurement is stated to be +-4°C over the whole operating range and +-2°C within a -20 to +85°C range provided the result is compensated for the sensor's non-linearity at temperatures below +20°C (the 2nd order compensation is described in the datasheet). My code also automatically offsets the result by -0.38°C to compensate for the supply voltage error as illustrated in respective chart at the end of the datasheet. The pressure measurement accuracy is stated to be +-350Pa but only between 300hPa to 1100hPa pressure levels within a -20 to +85°C range. Lower pressure levels down to 10hPa are said to be within the linear range of the ADC, but without any stated accuracy. A 2nd order compensation for temperatures below +20°C and additional compensation below -15°C must be included as well. Likewise, the pressure result is automatically offset by +190Pa to compensate for the voltage supply error. The calculations require the factory calibrated coefficients which are always polled from the module's PROM at tracker start-up. All the code can be found in the SPI and MS5607 libraries.

The ambient light sensor (VEML6030) is able to convert light intensities between 0.0072lx and 120klx to a digital value. The specific resolution and range of the sensor are dependent on selected gain and integration time. The communication with the sensor is carried out via I2C interface which allows sending commands to activate/shut down the sensor, set gain and integration time, request measurement data, etc. The respective code can be found in the I2C and VEML6030 libraries. The datasheet suggests starting with low gain and short integration time to cover the whole 120klx range followed by another higher gain/longer integration time measurement should the light intensity be too low. The downside of low light intensity and higher resolution measurements is an increase in active time and consumption of the sensor due to the longer integration time. To get a light intensity value in lux, the microcontroller multiplies the acquired raw measurement by a factor corresponding to a specific gain and integration time setting. For measurements above 1klx the code implements a compensation in accordance with the datasheet to correct for the sensor's non-linearity.

| Sensor | Min | Max | Resolution | Unit |

|---|---|---|---|---|

| MCU | -80.0 | +85.6 | 0.12 | °C |

| Thermistor | 0 | 4095 | 1 | ADC |

| MS5607_T | -80.0 | +85.6 | 0.02 | °C |

| MS5607_P | 0 | 753,570 | 1 | Pa |

| VEML6030 | 0.0072 | 110,083 | 0.0288-219 | lx |

| Battery Voltage | 0 | 4095 | 1 | ADC |

This table summarizes the form of data, the ranges of values, and the resolution the tracker actually transmits encoded in the APRS packet. Although the lower limit of the MCU's operating range is -40°C, should the ADC output lower values during a temperature measurement, the encoding can handle temperatures down to -80°C. The 0.12°C resolution of the transmitted values is due to the sensor's resolution. The 0.12°C value is also the maximum error due to averaging and rounding in the calculation.

In case of the two thermistors, the tracker transmits the raw 12-bit ADC output, and leaves the calculation to the receiver. Hence the parameters described in the previous table apply.

Similarly to the MCU's case, should the MS5607 report a temperature below its operating range, the encoding can handle values between -80.0°C and +85.6°C. The sensor's resolution of 0.02°C is the same as the resolution of the encoding. The maximum error due to rounding during on-board calculations and packet encoding/decoding is also 0.02°C. Pressure values beyond the operating range can also be transmitted. The packet encoding covers a 0 to 753,570Pa range. The sensor's quoted resolution is 2.4Pa while the encoding manages 1Pa resolution. Typical error due to rounding in calculations is around 1Pa.

In case of the ambient light sensor, the encoding was designed to cover almost the whole range stated by the datasheet. As described previously, this leads to decreasing resolution as the measured value increases. While the sensor itself produces measurements between 0 to 1887lx with a 0.0288lx resolution and between 0 to 120klx with a 1.8lx resolution, the encoding imposes its own resolution of 0.002lx at around 1lx measurements, 0.2lx at 100lx, 20lx at 10klx, all the way to 219lx resolution at the maximum value of 110,083lx. Due to the nature of the encoding, the minimum reported value by the tracker is 0.0072lx.

Just like in case of the thermistor, the battery voltage measurement is transmitted as the raw 12-bit ADC output. A follow-up calculation of the actual voltage at the receiver's side provides a 0.9mV resolution.

The two photos above show the setup during the sensor tests I did. The tracker supplied by a stable 1.5V LDO regulator typically mounted on a tripod or a small third hand.

First, I left the tracker transmitting measurements every 2s in a windowless storage room in my basement - the most stable environment I had at hand. In the chart on the left, the tracker took only single measurements and ADC readings. In the chart on the right on the other hand, the tracker set up the ADC to produce readings based on 64 averaged successive samples in case of the thermistor measurements where one sample takes 13 ADC clock cycles leading to 64 x 13 = 832 cycles of a 2MHz ADC clock - 0.4ms per ADC reading. Similarly, the MCU temperature is also an average of 64 samples, however this time the ADC was setup to take single samples, and the tracker looped over the ADC reading request 64 times. That meant the total time was prolonged by additional instructions. Regardless, the resulting reading still represented measurements attained within a few milliseconds. The MS5607 temperature readings were in both tests just single measurement requests. It is apparent that the thermistor and MS5607 measurements are quite stable with mutual offsets. The largest beneficiary of the averaging is then the MCU temperature measurement where originally successive samples varied by as much as 5°C while after averaging by only about 1°C.

These two charts show the pressure measurements taken during the previous tests. The two MS5607s were commanded to produce single measurements without any averaging. Similarly to the temperature measurements, there was a stable offset between the two modules. This side by side comparison nicely illustrates the magnitude of single module inaccuracies versus actual pressure fluctuations.

In the next test I did, I used the low winter temperatures to learn about the dynamic performance of individual sensors. The tracker was first kept inside for about 10 minutes, then taken out to face the cold environment before being brought back inside. All the time at the same altitude - important to avoid compromising pressure measurements. It is apparent from the data that the MCU and the onboard MS5607, both being soldered to the PCB, carry some thermal inertia compared to the other sensors which react very quickly to environmental changes. The PCB soldered MS5607 also seems to maintain its roughly 2°C offset from its sibling. The pressure readings then reveal how the measurement is impacted by the module's temperature. It is also worth noting that the resulting offset is larger in the external MS5607.

The MS5607 module's datasheet provides a chart outlining the typical error in pressure measurement due to temperature over the operating range at three different pressure levels.

These two charts, left for the onboard MS5607 and right for the external module, represent pressure offset with respect to temperature data as measured by the module collected during several tests - individual runs are differentiated by color. The offsets were calculated with respect to current pressure measured at around 20°C. During the tests, the tracker was either moved to a colder environment or warmed up. In other words, the charts show a portion of the same information for the two specific sensors on the TT7B tracker as shows the previous graph from the datasheet. Unfortunately, the lowest temperature at which I could test was only around -14°C. Some of the spread and variability in the data between individual runs and also within a single run is due to specifying the reference pressure and due to the fact that the actual absolute pressure slowly changed over the duration of a single test. Nevertheless, the trend is apparent. At room and higher temperatures the pressure measurements exhibit relatively small drift, while at temperatures down to -14°C, the pressure measurement is offset by up to -280Pa.

Another point of interest for me was stability of the offset in pressure measurements between the two modules with respect to absolute pressure levels since the tracker was expected to operate at much higher altitudes. To examine that, I put the tracker inside a simple vacuum chamber, and had it collect data at different pressure levels. The chart above shows the test starting at about 250hPa held for around 15 minutes. The test then continued by increasing the pressure level in steps all the way to ambient pressure. The green curve represents the offset of the external MS5607 with respect to measurements done by the onboard MS5607. As can be seen, it remained constant at around -110Pa throughout the test. The rapid spike during the initial pressure decrease could be due to the onboard MS5607 being closer to the air vent. The whole test was done at constant temperature - the onboard MS5607 measured 24°C and the external 22°C.

Because it was winter time, the weather was mostly cloudy, and I did most of the tests after sunset, I didn't at first notice a quite severe problem with the tracker. The two charts above capture a situation where the tracker was powered up inside, then after three minutes it was brought out into direct sunlight for about five minutes before being brought back inside. As can be seen, the moment the tracker was exposed to the Sun, the pressure readings went mad. The second chart containing measurements from the ambient light sensor revealed that the instant light intensity correlated with disruptions to the tracker's main 1.8V voltage. The progression of VCC was arrived at by using the battery voltage measurements with the knowledge that the tracker was supplied by a stable 1.5V regulator. In other words, since the measured voltage was constant, differing ADC output implied variation in the reference voltage - the main 1.8V supply. This led to a realization that both the boost converters reacted wildly to direct sunlight by changing their output voltage. A fact confirmed by a separate multimeter measurement as well.

I spent some time examining the behavior, trying different ways to shield various parts of the tracker, rereading datasheets, even measuring the feedback resistors whether they weren't light sensitive. In the end, I came across an application note by Silicon Labs that finally shed some light on the issue. AN0878: Methods of Reducing Light Sensitivity in CSP Packages provided me with some insight into how the boost converter's tiny package (WCSP Wafer-level Chip-Scale Package) differed from those that I was more accustomed to. Apparently, in case of the larger ICs in, for example, QFN packages, the silicon die is completely encapsulated in opaque epoxy and hermetically sealed from the environment. On the other hand, the CSP packages in an attempt to minimize the size of the IC more or less expose the die to its surroundings. This may result in incident light increasing the photocurrent in light sensitive parts of the IC. My guess is that in case of the TPS61099s, the direct sunlight interfered with the internal voltage reference which caused the boost converters to output higher and varying voltage. To eliminate this effect, the application note suggested casting the IC in a Glop Top epoxy compound.

I ordered a two part black epoxy encapsulation compound from a local seller called EPO-41. And after mixing the resin with the hardener in a more or less 4:1 ratio, I deposited a few drops of the mixture on and around both of the two boost converters and the SiT1552 TCXO which was also in a CSP package. Then after it was left to cure for over 24 hours, it was ready for further testing.

What I found out was that the voltage indeed became much more stable - a 10-15mV increase in direct sunlight (100klx). However, the pressure measurements were still misbehaving. After a few more tests, it became obvious that the pressure sensors themselves were sensitive to direct sunlight, though the datasheet did not mention anything on this topic. The issue seems to be related to two circular openings in the top metal enclosure. When shielded by a piece of black tape as in the images above, the sensors returned to normal behavior. The tape in both cases was not attached to the sensor itself, but rather arched over the sensor. The two charts then show the measured pressures, ambient light intensity and main 1.8V voltage during the test. The initial drop in pressure at around 7 minutes and eventual rise towards the end of the dataset were due to temperature as the tracker was brought outside and then back inside. At about 24 minutes into the test, the tracker was turned to face 90° away from the Sun. This decreased the temperature of the board and the onboard sensor by a few degrees, and let some sunlight inside the shield of the external sensor as it was no longer facing the Sun directly. Both of these effects can be seen in the pressure data and lower ambient light measurements.

In one of the photos by UBSEDS, I saw them using a roll of paper to shield a thermistor from direct sunlight. I thought this to be a reasonable idea and tried the same on TT7B. However, actual tests with one thermistor shielded and the other one left exposed showed the shield introducing more volatility to the measurements. The two charts above are the result of subtracting data from the external thermistor from the onboard thermistor data. In the first case, both thermistors were exposed to direct sunlight, while in the second case the onboard thermistor was shielded. The data show, beside the increased volatility, that during the day the shielded thermistor measured typically higher temperatures, while after sunset it reported lower temperatures than its exposed counterpart.

Following tests in different conditions, specifically behind a window in a roofed portion of a terrace, suggested the volatility could have been due to freely flowing wind in the original tests. The chart above shows the difference between the shielded onboard thermistor and the unshielded external thermistor when there was very little air circulation. The deviation peaked at around 2°C higher measurements from the external sensor. In the end, I decided to not use the shields and accept the potential 2 degree deviation of absolute temperature during peak irradiance.

The main purpose of all the sensors on TT7B is to measure differential pressure and temperature between the environment and conditions inside the balloon throughout the day. I tested this by sealing the external sensors inside an improvised balloon as can be seen in the images above, and pressurizing it with a pump. The resulting chart then illustrates the data I am after. The pressure plot is affected by the temperature dependent offset between the two sensors discussed earlier.